Find the Right Warehouse Facility: 8 Priorities

Inventory storage facilities are in high demand after years of supply chain disruption. In fact, availability in U.S. storage warehouses has fallen to near three percent vacancy over the last five years.1

With fewer storage options on the market, businesses that use third party warehouses or freight forwarders need to be aware that not all warehouse operators are created equal. Warehousing operations that disregard industry standards may put your products at increased risk of fire, water damage and theft.

Selecting the right facility is the first step to loss prevention. Knowing what questions to ask and industry best practices puts you in a better position to assess the quality of your warehousing partner. Before any contracts are signed, have a conversation with the warehouse operator or freight forwarder about available features, services provided, and risk management practices. Look for these essentials:

1. Property Security

A solid security program should include secured access, gates, fencing, security patrols, closed circuit television (CCTV) systems, proper exterior lighting and properly maintained windows. The perimeter of the location should be adequately protected with fencing and secured access points. Properties lacking in these qualities may expose your inventory to damage and theft.

2. Controlled Access to the Warehouse Area

Your inventory is precious cargo and should be stored securely with controlled access to the stock area. Safety measures should include CCTV and use of customer and employee ID cards that log and record access. It is also important to know if access is permitted outside of normal operating hours. Freight trucks dropping or picking up loads without warehouseman oversight may increase the risk of stolen or damaged property. Limiting access to stored goods can help protect against property loss.

3. Fire Prevention Measures

A quality warehouse operation should be prepared for safety issues with fire prevention programs, including private protection and control of common and special hazards. The warehouse should have central station fire alarms and monitoring of heat, fire and smoke. Sprinkler systems should be appropriately sized and to current standards.

4. Proper Overflow Solutions

With such a shortage of storage facilities, some warehouses are moving to parking lots and other outdoor storage for container overflow. A quality warehouse will not leave materials and merchandise outside where it may be exposed to the elements and risk of theft and damage.

5. Onsite Emergency Backup Power

If backup power is not available and in good working condition on-site, product damage can occur. In refrigerated storage facilities, flood-related power outages may cause temperature changes, which can damage perishable or heat-sensitive goods.

6. Compatibility of Goods and Services

Different products and materials located near each other may create special hazards and increase the potential for exposure and loss. Stowing your cargo with compatible inventory is important to keeping it safe from risks like fire, moisture and odors.

7. Inventory Management Systems

Warehouse facilities should have a computerized inventory tracking system where all stock received and sent out is scanned, creating an up-to-date inventory of goods on hand. Without sufficient inventory management, it can be difficult to settle a claim or assess liability should an incident arise.

8. Workforce Management

Ask about employee hiring and safety procedures. Proper hiring practices, onboarding and continuous training should be provided to all employees, including pick and pack personnel. Attention to workplace best practices can help ensure heavy equipment operators handling your items will be safe and reliable.

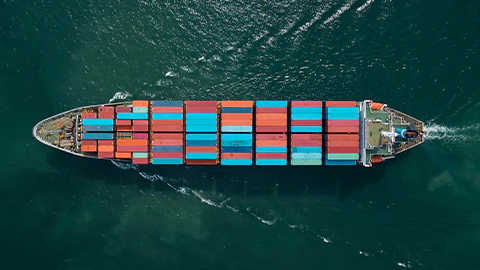

Warehouse facilities play a vital role in the more than $54 billion (nearly 55 million tons) of freight moved around the country each year. Understanding what to look for in a storage facility will enable you to keep your inventory safe, secure and accessible when you need it.

Sources

2 https://data.bts.gov/stories/s/Moving-Goods-in-the-United-States/bcyt-rqmu/