Business Resources

Putting insights and expertise to work for your business

Industries

Resources for Nonprofit Organizations

5 Tips for Recruiting Nonprofit Board Members

Recruiting nonprofit board members is challenging. Get recruitment ideas for filling those seats.

Resources for the Energy Industry

6 Tips to Help Stop Distracted Driving at Solar and Wind Farms

Wind and solar installations are often in remote locations, requiring driving on the job. Help protect employees from the dangers of distracted driving.

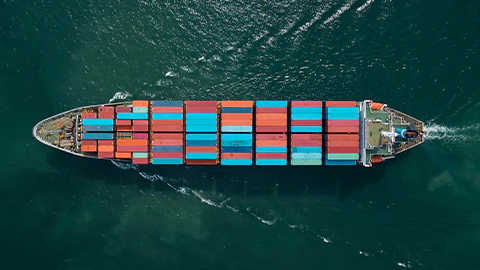

Supply Chain Risk Management Resources

Life of a Piece of Cargo

There’s a lot that can happen to cargo on its journey. Protecting yourself from these cargo-related risks is key to protecting your supply chain.

Topics

Facilities Management Safety Tips and Resources

Tips to Help Keep Employees and Visitors Safe in Parking Lots

Slippery conditions, uneven surfaces and poor lighting can make parking lots and garages hazardous for employees and visitors. Explore tips to help keep your parking lots safe.

Resources for Technology

The Impact of Emerging Technology on Equipment

Learn how emerging technology is impacting equipment breakdown and five ways companies can prepare to be more resilient.

Cyber Resources

5 Types of Cybercriminals and How to Protect Against Them

Understanding the types of cybercriminals and their techniques can help protect your organization from a data breach.

Surety bonds

DISCOVER MORE

The right business insurance coverage to protect your company

For businesses of diverse industries and sizes, Travelers offers comprehensive insurance solutions designed to address risk across a spectrum of operations.