Supply Chain Management Tips

Your business may be held liable for every step in your supply chain. Here are some tips on how to know as much as you can about who and where your parts, products and services come from.

SUPPLY CHAIN MANAGEMENT TIPS

Did You Know 27% of business worry about being unable to get products to customers?1

Your business may be held liable for every step in your supply chain.

Regulatory Oversight

Maintain constant oversight of your suppliers’ policies and practices to make sure they comply with safety, environmental and industry regulations.

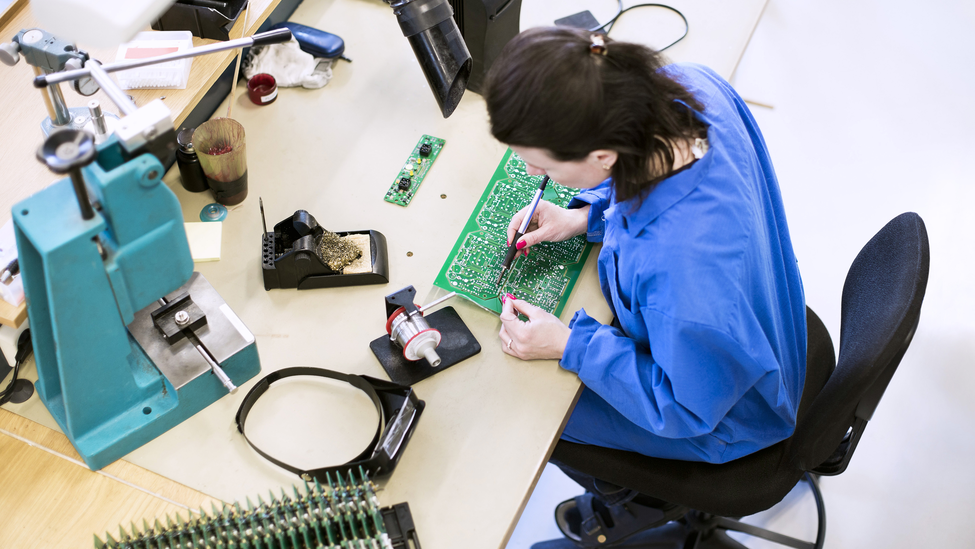

Counterfeit Parts

Knowing how to identify counterfeit parts is helpful. Rigorous planning and oversight of vendor selection criteria, engineering controls, component sampling, inspection and testing is key, too.

Overseas Suppliers

When parts, components or suppliers come from overseas, verify that they meet your specifications and quality expectations, as you may be fully liable for them.

Consumer Demand

If your customers have specific demands, like earth-friendly products, fair-trade labor practices or clean technology, you should make sure your suppliers meet these expectations.

Have a Backup Plan

Change is constant. Every time you change suppliers, re-evaluate and re-ensure that the proper regulatory, environmental, safety and backup standards and controls are in place and practiced.

Share this infographic with your coworkers and associates to help them #HarnessRisk.

Visit www.travelers.com/resources/supply-chain-management for more supply chain safety tips for your business.

1https://www.travelers.com/iw-documents/resources/risk-index/2016-report.pdf

The Travelers Indemnity Company and its property casualty affiliates. One Tower Square, Hartford, CT 06183

travelers.com

This material does not amend, or otherwise affect, the provisions or coverages of any insurance policy or bond issued by Travelers. It is not a representation that coverage does or does not exist for any particular claim or loss under any such policy or bond. Coverage depends on the facts and circumstances involved in the claim or loss, all applicable policy or bond provisions, and any applicable law. Availability of coverage referenced in this document can depend on underwriting qualifications and state regulations.

© 2017 The Travelers Indemnity Company. All rights reserved. Travelers and The Travelers Umbrella logo are registered trademarks of The Travelers Indemnity Company in the U.S. and other countries.